We streamline processes to make your supply chain market-ready!

At Dawn India, we go beyond customs broking and warehousing to ensure your products are market-ready. Our value-added services enhance operational efficiency, streamline processes, and minimize delays. With a focus on precision and technology-driven execution, we help you save time, reduce costs, and scale your business with confidence.

We group multiple products together into a single package for easy handling and sales.

Reduces packaging costs, improves efficiency, and is ideal for promotional or seasonal product offerings.

Pre-assembling individual items into ready-to-ship kits.

It improves order accuracy and speeds up distribution.

We apply accurate product labels to meet regulatory and branding requirements.

It enhances traceability and improves product presentation.

Ensuring that all product packaging designs meet branding and compliance standards.

This helps maintain brand consistency, regulatory adherence, and market readiness.

We reconfigure packaging to meet specific market needs or customer preferences.

Helps with rebranding, regulatory compliance, and damage prevention.

Wrapping products in a plastic film that tightens when heated, securing items together.

Protects against dust, moisture, and tampering while improving shelf appeal.

Encasing products in pre-formed plastic blisters for visibility and protection.

It enhances durability, prevents contamination and improves retail display.

Producing high-quality labels for packaging and product identification.

This helps improve the shelf appeal, provides essential product details, and ensures compliance with industry standards.

We group multiple products together into a single package for easy handling and sales.

Reduces packaging costs, improves efficiency, and is ideal for promotional or seasonal product offerings.

Pre-assembling individual items into ready-to-ship kits.

It improves order accuracy and speeds up distribution.

We apply accurate product labels to meet regulatory and branding requirements.

It enhances traceability and improves product presentation.

Ensuring that all product packaging designs meet branding and compliance standards.

This helps maintain brand consistency, regulatory adherence, and market readiness.

We reconfigure packaging to meet specific market needs or customer preferences.

Helps with rebranding, regulatory compliance, and damage prevention.

Wrapping products in a plastic film that tightens when heated, securing items together.

Protects against dust, moisture, and tampering while improving shelf appeal.

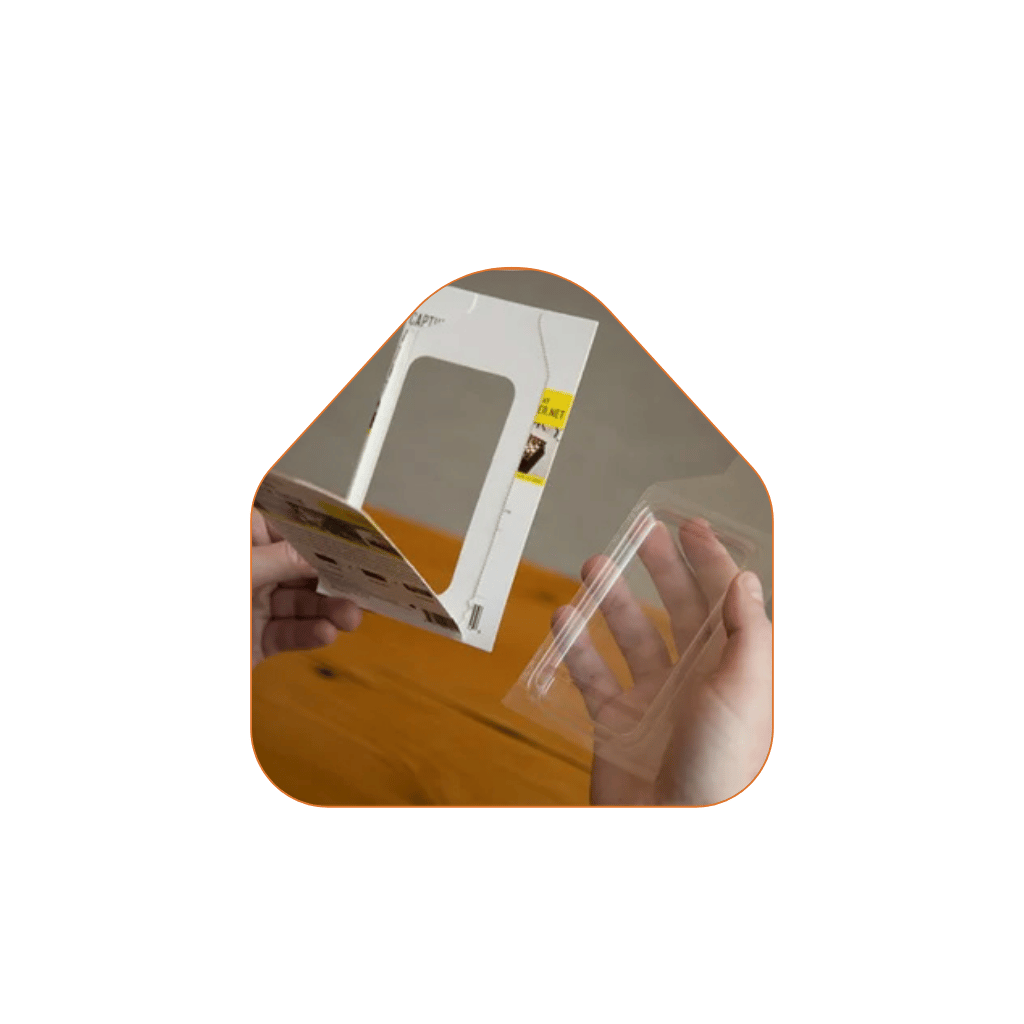

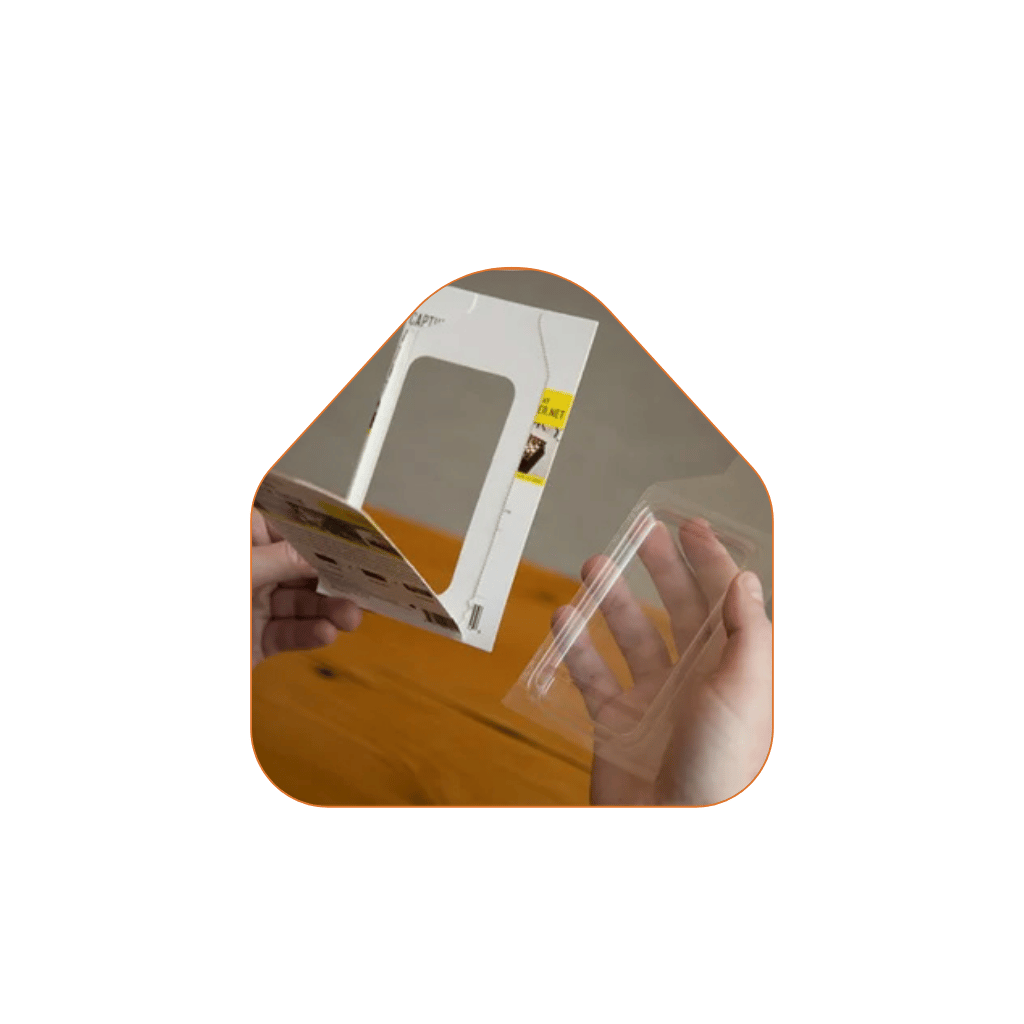

Encasing products in pre-formed plastic blisters for visibility and protection.

It enhances durability, prevents contamination and improves retail display.

Producing high-quality labels for packaging and product identification.

This helps improve the shelf appeal, provides essential product details, and ensures compliance with industry standards.

In-process Quality Checks (IPQC) at regular intervals

411 – 413, Apeejay House, 130 Mumbai Samachar

Marg, Fort, Mumbai – 400 023

D-1, RK Infra Modern Logi Park, Sawad Naka Road,

Bhiwandi – 421302

© Copyright 2026 – Dawn India, All rights reserved.